SP 3-872-009 Shut Down Harness: Complete Guide

If you’re here, it’s probably because you’ve encountered the SP 3-872-009 shut down harness. You may have heard about its role in industrial machinery or maybe you need a replacement for your existing setup. Whatever the case, understanding this specific component can be crucial for maintaining the safety and efficiency of your equipment. Don’t worry, I’ve got you covered. In this article, we’ll dive deep into the world of the SP 3-872-009 shut down harness, explaining what it is, how it works, and why it’s an essential part of many industrial systems. We’ll also walk you through installation tips, troubleshooting, and maintenance practices to ensure everything runs smoothly.

What Is an SP 3-872-009 Shut Down Harness?

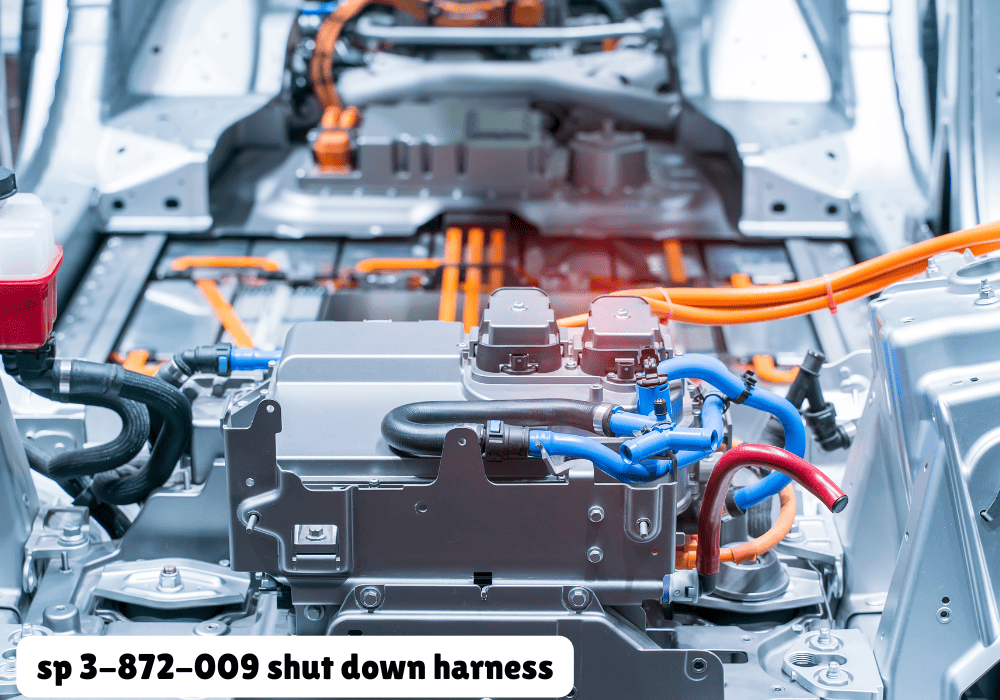

Before we dive too deep, let’s clarify what exactly we’re talking about. The SP 3-872-009 shut down harness is a specialized wiring component used in various industrial and automotive systems to ensure that a piece of machinery can be safely powered down. It’s specifically designed to facilitate an emergency shutdown when needed, preventing machinery from operating under unsafe conditions.

These harnesses are typically used in high-stakes environments like power plants, factories, and even in complex automotive setups. Their purpose is not just to stop the equipment but to ensure that the shutdown process is safe, controlled, and happens without any collateral damage.

Why Is the SP 3-872-009 Shut Down Harness Important?

The SP 3-872-009 shut down harness isn’t just another wiring piece; it’s a safety feature. Industrial machinery can be dangerous, especially if something goes wrong, such as overheating, electrical failure, or a mechanical issue. A shut down harness ensures that in the event of a malfunction, the machinery can be safely and quickly powered down. This can prevent severe damage to the machine, reduce downtime, and most importantly, protect the people working around it.

Key Features of the SP 3-872-009 Shut Down Harness:

- Reliable Emergency Shutdown: When activated, the harness ensures a quick and controlled shutdown of the machine, protecting equipment from potential damage.

- Durability: Designed for industrial environments, the harness can withstand harsh conditions like heat, moisture, and physical wear.

- Ease of Installation: Though it may seem complex, the SP 3-872-009 shut down harness is typically straightforward to install for those familiar with industrial systems.

- Compatibility: The harness is compatible with a variety of machines and systems, making it versatile in its applications.

How SP 3-872-009 Shut Down Harness Work?

At its core, the SP 3-872-009 shut down harness is essentially a wiring network designed to control the flow of electrical signals in and out of a system. When the shutdown sequence is triggered—either manually by an operator or automatically by a system malfunction—this harness cuts off the electrical supply, effectively powering down the machine.

But it’s not just about flipping a switch. The harness ensures that the shutdown process happens in a controlled manner. In some cases, certain components of the machine need to be powered down in a specific sequence to avoid damage. The SP 3-872-009 harness handles all of that.

Typical Applications:

- Power Plants: In these high-energy environments, machinery must shut down safely to prevent electrical fires or explosions.

- Factories: With countless moving parts and machines, a shut down harness ensures that malfunctions don’t lead to safety hazards.

- Automotive Systems: In some cases, particularly in heavy-duty vehicles, this type of harness is used to ensure safe shutdown during electrical or mechanical issues.

Installation Tips for the SP 3-872-009 Shut Down Harness

Installing a shut down harness can seem daunting, especially if you’re new to working with industrial machinery. However, with some patience and attention to detail, it’s a task you can manage.

Prepare Your Tools

You’ll need a variety of tools to install the SP 3-872-009 shut down harness properly. Make sure you have:

- Wire strippers

- A multimeter

- Electrical tape

- Screwdrivers and pliers

- Connectors and fasteners specific to your machine

Understand the Wiring Diagram

Before diving in, take the time to familiarize yourself with the wiring diagram that comes with the shut down harness. Understanding where each wire goes is crucial for a successful installation. If you don’t have a diagram, consult with a technician or reach out to the manufacturer.

Turn Off the Power

This is non-negotiable. Before installing the harness, ensure that the machine is completely powered down and disconnected from its power source. This prevents accidental electric shocks and also protects your equipment.

Connect the Wires

Using the wiring diagram as a reference, start connecting the wires from the SP 3-872-009 shut down harness to the corresponding terminals on your machine. Be careful to match colors and ensure that each wire is securely fastened.

Test the Harness

Turn the power back on and manually trigger the shut down sequence to ensure that the harness is working correctly. Use your multimeter to check that electrical signal are being properly transmitted.

Secure the Wiring

After confirming that the harness works, make sure all wires are securely fastened and protected. Use electrical tape to cover any exposed wires and fasten them to the machine to prevent any damage from movement or vibrations.

Common Issues and Troubleshooting

No system is perfect, and sometimes the SP 3-872-009 shut down harness might experience issues. If your system isn’t shutting down as it should, here are some common problems and how to troubleshoot them.

Loose Connections

One of the most frequent problems is a loose wire or connector. This can prevent the harness from receiving or sending the necessary signals. Double-check all of your connections and ensure that each wire is securely fastened.

Damaged Wiring

Industrial environments can be harsh, and over time, wires may get frayed or damaged. Inspect the entire harness for any visible wear and tear. If you notice any issues, replace the damaged wiring immediately.

Faulty Switch

Sometimes the issue lies not in the harness but in the switch that triggers the shutdown.

Electrical Interference

In some cases, electrical interference from nearby machinery can disrupt the signals in the shut down harness. Try repositioning the harness or adding shielding to reduce interference.

Maintenance Practices for Longevity

To ensure the longevity of your SP 3-872-009 shut down harness, it’s important to carry out regular maintenance. Like any other industrial component, a well-maintained harness will function more reliably and last longer.

Regular Inspections

Perform routine visual inspections of the harness and its wiring. Look for signs of wear and tear, including fraying, discoloration, or exposed wires.

Clean the Connectors

Dust, dirt, and grime can accumulate on the connectors over time, reducing their effectiveness. Clean the connectors regularly using a soft cloth and an appropriate cleaner to ensure a good connection.

Replace Worn Parts

If any part of the harness starts showing signs of wear, don’t hesitate to replace it. A small investment in replacement parts can save you from costly machinery repairs in the future.

Check for Corrosion

Corrosion can develop on the connectors or wiring if the harness is exposed to moisture. During your inspections, check for any signs of corrosion and address them immediately by cleaning or replacing affected parts.

Alternatives to the SP 3-872-009 Shut Down Harness

While the SP 3-872-009 shut down harness is a solid option, it’s not the only one on the market. Depending on your specific needs, you might consider alternative shut down systems. Here are a few other options:

- Automatic Shutdown Controllers: These are more sophisticated systems that can manage the shutdown process based on pre-programmed conditions.

- Manual Shutdown Switches: A simpler alternative for smaller machinery, manual switches offer immediate shutdown capabilities without the complexity of a full harness.

- Wireless Shutdown Systems: For some industries, wireless shutdown systems provide more flexibility, allowing operators to shut down machines remotely.

How to Choose the Right Shut Down Harness for Your System

Choosing the right shutdown harness isn’t always straightforward. With various options available, how do you ensure that the SP 3-872-009 shut down harness is the right one for your system?

Check Compatibility

First and foremost, ensure that the SP 3-872-009 shut down harness is compatible with your machine. Check the manufacturer’s specifications for both the harness and your equipment to make sure they’re a match.

Consider Your Environment

If your machinery operates in harsh conditions—like extreme heat, moisture, or dust—you’ll need a harness that can withstand these challenges. The SP 3-872-009 is known for its durability, but always verify that it meets your environmental needs.

Evaluate the Installation Requirements

How complex is the installation process? If you don’t have a lot of technical expertise or resources available, choose a harness that’s easy to install and maintain.

Think About Maintenance

Some harnesses require more frequent maintenance than others. If you want a low-maintenance option, ensure that the harness you choose doesn’t require constant attention.

FAQs About the SP 3-872-009 Shut Down Harness

1. What industries typically use the SP 3-872-009 shut down harness?

The SP 3-872-009 shut down harness is commonly used in industries that rely on heavy machinery, such as manufacturing, power plants, and automotive systems.

2. Can I install the SP 3-872-009 shut down harness myself?

Yes, with the right tools and some knowledge of electrical systems, you can install the SP 3-872-009 shut down harness.

3. How long does the SP 3-872-009 shut down harness last?

The lifespan of the harness largely depends on its environment and how well it’s maintained.

4. What should I do if the SP 3-872-009 shut down harness fails?

If the harness fails, immediately shut down your machinery and inspect the wiring for damage. Replace any faulty components and test the system before restarting.

5. Is the SP 3-872-009 shut down harness compatible with all machines?

Not all machines are compatible with the SP 3-872-009 shut down harness. Always check the manufacturer’s specifications to ensure it will work with your system.

Conclusion

In conclusion, the SP 3-872-009 shut down harness is an essential component for ensuring the safe and reliable operation of industrial machinery. Its role in controlled shutdown processes can prevent costly damage and protect workers. By understanding how it works, installing it correctly, and maintaining it regularly, you can keep your equipment running smoothly for years to come.